Wet blasting (also known as vapor blasting, vapour blasting or aqua blasting) has numerous applications and benefits for aerospace Maintenance, Repair, and Overhaul (MRO) operations.

Click on the subject area relevant to your MRO operation to learn about the associated wet blasting applications and benefits.

Wet shot peening turbine and fan blades

Wet shot peening turbine and fan blades  Engines

Engines  Wheels and brakes

Wheels and brakes  Composite and additive manufactured components

Composite and additive manufactured components  Undercarriages

Undercarriages  Propeller and helicopter blades

Propeller and helicopter blades  Toilets

Toilets  General benefits of wet blasting for MRO operations

General benefits of wet blasting for MRO operations  Automatic and manual wet blasting machines for Aerospace MRO

Automatic and manual wet blasting machines for Aerospace MROContact us if you already know your MRO wet blasting requirements

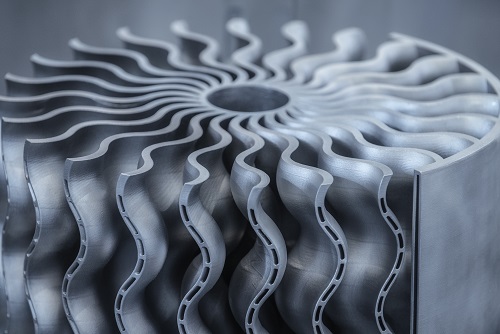

Wet shot peening turbine and fan blades

Wet shot peening turbine and fan blades

The lifespan of a turbine blade can be extended more than 1000% by wet shot peening. The process involves projecting small hard spherical media particles at turbine blades, fan blades, or any other engine components that need strengthening. It is a very effective way of improving fatigue strength. As well as peening to the same intensity as dry blasting (with all the benefits over dry blasting mentioned below) it is gentler on more delicate surfaces thanks to the cushioning effect of water.

By bombarding a turbine or fan blade with the peening blast media the blade’s substrate becomes exposed to compressive stresses that improve strength by giving the grain structure a shallower depth with a more random texture pattern. This change to a surface’s structure through peening makes it far less likely to fracture and crack.

Typically peening is used on components that are irregular in shape and that may be subject to twisting and bending stresses. Users of the wet peening process on components like these have recorded significantly increased product life and quality across a range of industries, including jet engine MRO.

There are several other benefits our customers have experienced when wet shot peening aerospace fan and turbine blades compared with their legacy dry shot peening systems, including:

Wet shot peening meets or helps meet the requirements for the following industry specifications, amongst others:

|

Document Number |

Document Title |

Manufacturer |

|

AMS 2432 |

Shot peening, computer-controlled |

Multiple OEMs |

|

POP 392-AR |

Wet glass bead peening to PWA 36906 |

Pratt and Whitney |

|

RPS 428 |

Controlled blasting and peening for fatigue resistance |

Rolls-Royce |

|

P11TF8 |

Metallic shot peening |

GE |

|

DMP28 |

Surface compressive stressing |

SNECMA / Safran |

|

32-09-01 |

Glass bead peening of light alloy parts |

Safran |

See the full list of specifications our wet blasting technology can help you achieve.

Contact us to discuss your turbine blade, fan blade or other engine component peening requirements

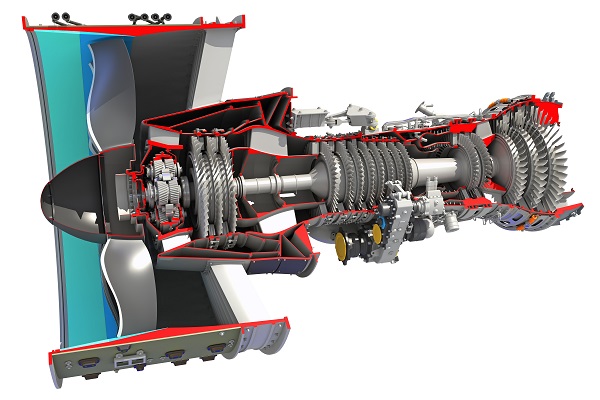

Engines

Engines

When it comes to MRO operations for jet engines, our highly versatile wet blasting process can:

Wet blasting is applicable to most engine components, including:

Surface preparation for coatings and the creation of technical surfaces

Wheels and brakes

Wheels and brakesThe benefits of wet blasting for wheel and brake shop managers

Removing multiple coating layers, oils, grease, and all contaminants in one operation delivers significant time and cost savings for MRO wheel and brake shops compared with manual and chemical stripping processes. Our wet blasting formula has been proven to be the fastest way to de-paint wheels and brakes.

Aircraft wheel and brake cleaning for MRO

Wheels and brakes are put under enormous stress when landing and require regular non-destructive testing (NDT) to ensure they remain safe.

For accurate and safe inspection, wheels and brakes must be thoroughly cleaned for NDT methods like eddy current testing (ECT). However, the cleaning process can be time-consuming and laborious, potentially tying up a skilled inspector's time.

Using our specially developed formula of plastic media, mild detergent, hot water, and air, wet blasting thoroughly and rapidly cleans aircraft wheels and brakes, removing oils, grease, brake dust, corrosion, heat scale, and thanks to the flowing nature of the wet blast slurry (a wet blast slurry simply consists of water and abrasive media), it can completely clean the most complex of wheel geometries.

With a blast formula set for wheel or brake cleaning, wet blasting does not damage painted layers, instead, it effectively simulates hand scrubbing without the laborious manual effort.

Wheels and brakes are rapidly and thoroughly cleaned leaving more time for inspection and in turn, increasing the capacity of the wheel and brake shop operation.

As an added operator / environmental health benefit, brake dust, chromium particles in some primers, and other potentially harmful contaminants are held within the water of the wet blast slurry, so unlike dry blasting and some other finishing processes, there is no risk of inhalation.

Aircraft wheel coating removal for MRO

After a certain amount of use, wheels and brakes need more rigorous NDT requiring coatings like paints, primers, sealants, thermal barrier coatings, and other coatings to be removed. Using the same specially developed formula described above for wheel and brake cleaning, and at the touch of a button, higher air pressure can be used to rapidly remove multiple layers of coatings along with oils, grease, brake dust, and all other contaminants in one operation and without damaging the wheel or Alodine or anodised layer.

The effect of wet blasting aircraft wheels

The highly controllable process is operator friendly and requires no hand scrubbing or harmful chemicals.

An additional benefit over dry blasting methods is the elimination of the separate wheel and brake washing, hand scrubbing, and drying stages that must be carried out before dry blasting.

Dry media blasting tends to be slower, creates dust, and does not always protect operators from potentially harmful paint dust particles. With the need to degrease wheels before dry blasting and with the risk of concealing cracks via over-peening, dry blasting can negatively affect NDT and safety.

With our wet blasting formula, there is no risk of peening the surface. The flowing nature of wet blasting exposes cracks by cleaning them rather than concealing them, making them more visible during NDT, improving inspection accuracy, speed, and subsequent safety.

The effect of wet blasting cracks with our plastic media blast formula

Wet blasting makes a significant contribution to meeting NDT standards, including the American Society for Non-Destructive Testing (ASNT), the British Institute of Non-Destructive Testing, the International Committee for Non-Destructive Testing, and the European Federation for Non-Destructive Testing. It also helps meet ISO and American Society for Testing Materials (ASTM) standards.

Contact us to discuss your wheel and brake MRO wet blasting requirements

Composite and additive manufactured components

Composite and additive manufactured components

The combination of strength and light weight makes composites ideal for use in aerospace. Wet blasting can clean and strip coatings from composite surfaces just as effectively as it can from metal surfaces and perfectly prepares composite surfaces for bonding and coatings like paint and lacquer, without damaging composite fibres.

When it comes to bonding, the ‘wet out’ surface wet blasting creates ensures optimal coverage of coatings and adhesives and in turn maximum bond strength and safety.

Wet blasting is therefore highly relevant to MRO operations working with composite fan and turbine blades, propellers, helicopter rotor blades and other composite aerospace components.

Learn more about wet blasting composite components by visiting our dedicated industry page.

Additive manufactured (AM) aerospace components

Thanks to advances in additive manufacturing, a significant number of aerospace components are now manufactured using AM technologies. Wet blasting is highly suited to cleaning, de-painting, and preparing metal, composite, and polymer AM aerospace components for NDT or coatings like paints and oils.

It is also particularly effective at clearing powder, partially sintered powder, and other contaminants from the complex internal channels that are often a feature of AM components, giving a visual indication that the channel is clear when blast media appears. In contrast, it is not only difficult to tell if a channel is clear with dry blasting, it can even compound issues by adding additional blast media to blocked channels.

Contact us to discuss your composite or AM component MRO wet blasting requirements

Undercarriages

Undercarriages

In addition to aircraft wheels and brakes (see the section on 'wheels and brakes' above), wet blasting can be applied to other undercarriage components too, like landing gear struts, shock absorbers, retraction mechanisms, locking mechanisms, doors and fairings, fixings and other smaller components.

Applications for wet blasting include cleaning - removing oils, grease, and other contaminants in one operation without damaging under-lying painted layers, de-painting, de-lacquering, and preparation for various NDT methods including eddy current testing (ECT) and dye penetrant testing.

See the section on ‘Fixings and other small components cleaning’ below for an explanation of how wet blasting applies to smaller components.

Contact us to discuss your undercarriage component MRO wet blasting requirements

Propeller and helicopter blades

Propeller and helicopter blades

As with other aerospace components, propeller blades need to be thoroughly cleaned and often de-coated / de-painted prior to NDT testing. Traditionally, this has either been done by hand, chemicals, or dry blasting, all of which have significant disadvantages when compared with wet blasting.

Cleaning by hand is time-consuming and laborious, chemicals can be harmful, difficult to dispose of, and slow to clean or de-coat propellers, especially if multiple stages are required. Dry blasting involves cleaning the propeller first, removing all oils, grease, and other contaminants, drying before blasting, and then residual dust and blast media removed after coating, making the process lengthy and with significant health and safety issues. In addition, dry blasting can result in an uneven finish when compared with wet blasting.

Our specially developed wet blasting formula of plastic media, mild detergent, hot water, and air, rapidly cleans and de-paints propeller and helicopter blades. Blades can be cleaned only, removing corrosion, grease, oils, and other contaminants, or, at the press of a button, the air pressure can be increased to simultaneously clean and de-paint blades.

When it comes to metal propeller blades, the fast and clean wet blasting process leaves blades clean and de-painted ready for Alodine or anodised layers to be chemically removed in preparation for NDT dye penetrant testing for cracks. The main benefit here is the removal of harmful chemicals or laborious hand cleaning and paint stripping processes.

Crucially the wet blasting process, even when de-painting, does not remove material from the propeller or helicopter blade itself.

Wet blasting can also be used to create the perfect surface for re-painting or bonding, bonding of de-icing pads for example.

As well as processing metal blades, wet blasting can replace time-consuming manual sanding when it comes to preparing composite propeller blades for NDT crack detection. As with metal blades surfaces can be perfectly prepared for coatings like paint and lacquer or adhesives for bonding, especially important if the leading edge needs to be replaced due to damage.

Composite fibres are not damaged during wet blasting thanks to the cushioning effect of water in the wet blasting process.

Propeller hubs, governors, and other propeller components can be cleaned and prepared for NDT in the same way as blades, including smaller items, see the ‘Fixings and other small components cleaning’ section below.

Contact us to discuss your propeller or helicopter blade MRO wet blasting requirements

Toilets

Toilets

Wet blasting offers the opportunity for hygienic and safe toilet component cleaning. In one operation it cleans fixed and smearable contamination and creates surfaces that are harder for ‘dirt’ to adhere to. In addition, the process creates surfaces that are easier to clean, look better and are more hygienic. Components that can usually be wet blasted include pans, pipework, pumps, and tanks.

The wet blasting cabinet (vapor blasting cabinet, vapour blasting cabinet or aqua blasting cabinet, to give it its other names) keeps the operator shielded whilst blasting the toilet component. Our customers have found the shielding an important benefit when there are concerns over the spread of diseases.

Contact us to discuss your toilet MRO wet blasting requirements

General benefits of wet blasting for MRO operations

General benefits of wet blasting for MRO operationsAutomation: Most of our wet blasting machines installed in jet engine MRO operations are automatic. That is because they deliver a highly consistent result every time and of course there are significant productivity improvements too. In such a regulated industry, consistent results are essential. Consistency coupled with improved productivity ensures rapid ROI on our automatic machines.

Process control: The use of water in wet blasting helps control the surface finish more precisely compared with dry blasting methods. Wet blasting is significantly more controllable than other surface finishing processes. Operators can adjust parameters such as blast pressure, water flow rate, and abrasive media type to achieve the desired surface roughness (Ra) and cleanliness levels, crucial for aerospace component performance and longevity. Our control and automation page explains these parameters in greater detail.

Versatility: From cleaning wheels and fan blades to removing paint to wet shot peening, wet blasting is a highly versatile process. This allows MRO operations to use wet blasting for a multitude of different applications. It is a process that can be adapted easily, making it ideal for unskilled manual operation.

Gentle cleaning: Wet blasting utilises a combination of water, abrasive media, and compressed air to gently remove contaminants, coatings, and corrosion from delicate aerospace components without causing damage. This is particularly beneficial for sensitive parts like engine components, turbine blades, and intricate surfaces where other blasting methods might be too harsh. Composite fibres and Alodine layers are not damaged by the process.

Reduced dust and contamination: Wet blasting suppresses dust and airborne contaminants by trapping them in the water stream, resulting in a cleaner and safer working environment. This is especially important in aerospace MRO facilities where strict cleanliness standards are necessary to prevent foreign object debris (FOD) and maintain component integrity.

Improved operator safety: In addition to reducing harmful airborne particles and abrasive dust, the use of water can mitigate the potential for static electricity buildup, which is important when working with flammable materials commonly found in aerospace applications.

Another safety benefit is the noise level wet blasting generates which typically operates below 80 dBA vs. dry blasting at approx. 90 dBA and over. The US Occupational Safety and Health Administration (OSHA) requires employers to implement a hearing conservation program when noise exposure reaches 85 dBA averaged over 8 working hours, or an 8-hour time-weighted average (TWA). This means ear defenders are not required when wet blasting.

Environmental Friendliness: Wet blasting is a more environmentally friendly alternative to most other surface preparation methods. It typically generates less waste and eliminates the need for harsh chemicals, making it a greener option for aerospace MRO operations.

Effluent from the machine is processed through a filtration system, enabling solid waste to be separated for safe, no toxic, disposal, and for the water to be recycled.

Fixings and other small components cleaning: We have several wet blasting machines with barrel options for smaller components, removing the need to clean individual parts by hand, which is prohibitively costly.

Fixings like bolts, screws, and other small components, e.g. smaller gear parts, are loaded into the barrel, blasted on a set program, rinsed, and dried ready for inspection and re-use. Crucially, wet blasting, unlike dry blasting, preserves delicate edges, threads, and plated surfaces. It also preserves the cadmium plating that prevents oxidation of some fixings.

Contact us to discuss any of the points above that are relevant to your MRO operation

Overall, wet blasting offers aerospace MRO facilities a highly versatile and efficient solution for cleaning, surface preparation, and refurbishment of numerous critical components, helping to maintain aircraft safety, reliability, and performance.

Read our case studies to find out how our wet blasting machines are helping aerospace organisations with their MRO requirements. Read our white papers for a deep dive into specific MRO applications.

Explore our automatic and manual wet blasting machines section below to gain a better understanding of what our machines can do. Videos, technical specifications, images, etc. are available for each wet blasting machine (also known as vapor blasting machine, vapour blasting machine and aqua blasting machine).

Contact us if you already know your MRO wet blasting requirements

Our wet blasting technology can help support the following requirements of the following specifications

|

Aerospace specifications our wet blasting can help support Our wet blasting technology can help support the following requirements of the following specifications |

||

|

Document Number |

Documents Title |

Airframe Manufacturer |

|

208-13-40 |

Shot and glass bead peening |

Triumph Vought |

|

208-9-146 |

Aqueous degreasing |

Triumph Vought |

|

ABP1-2028 |

Shot peening for improved fatigue and stress corrosion resistance |

Airbus |

|

ABP1-2344 |

Cleaning and surface improvement blasting |

Airbus |

|

ABP5-1351 |

Surface preparation prior to application of paints |

Airbus |

|

ABP8-1290 |

Cleaning and degreasing of metallic materials |

Airbus |

|

ABP8-1294 |

Cleaning & degreasing of metallic materials |

Airbus |

|

ABP8-1296 |

Deoxidation of aluminium alloys |

Airbus |

|

AIPS02-02- 003 |

Wet blasting |

Airbus |

|

AMS-S 13165 |

Shot peening of metal parts |

Multiple OEM's |

|

AMS2430 |

Shot peening |

Multiple OEM's |

|

AMS03-2 |

Cleaning and preparation of metal surfaces |

Multiple OEM’s |

|

ASTM-B-600 |

Descaling and cleaning titanium and titanium alloy surfaces |

Multiple OEM's |

|

BAC5730 |

Shot peening |

Boeing |

|

BAC5751 |

Cleaning, descaling and surface preparation of ferrous alloys |

Boeing |

|

BAC5753 |

Cleaning, descaling and surface preparation of titanium and titanium alloys |

Boeing |

|

BAC5758 |

Cleaning, descaling and surface preparation of nickel and cobalt base alloys |

Boeing |

|

BAC5765 |

Cleaning and deoxidizing aluminium alloys |

Boeing |

|

BAC5769 |

Cleaning, descaling and surface preparation of magnesium alloys |

Boeing |

|

BAC5770 |

Cleaning, descaling and surface preparation of Boeing copper alloys |

Boeing |

|

BAC5771 |

Stripping inorganic finishes |

Boeing |

|

BAC5951 |

Glass bead peening (S/S by BAC5730) |

Boeing |

|

BAPS 180- 007 |

Vapour degreasing |

Bombardier |

|

CSFS037 |

Abrasive cleaning of metals |

Cessna |

|

CSFS040 |

Paint stripping |

Cessna |

|

CSFS042 |

Vapor degreasing |

Cessna |

|

CVA13-1 |

Blast Cleaning of Metal Parts |

Triumph Vought |

|

CVA9-17 |

Treatment of metallic surfaces for paint adhesion |

Triumph Vought |

|

DPS4.999 |

Shot peening of metal parts |

Douglas |

|

DPS9.014 |

Cleaning copper and copper Alloys |

Douglas |

|

DPS9.05 |

Cleaning of carbon steels and low alloy steels |

Douglas |

|

DPS9.301 |

Cleaning aluminium alloys |

Douglas |

|

DPS9.341-1 |

Aqueous degreasing |

Douglas |

|

FSI-PS-4020 |

Cleaning of aluminium, steel and cres |

Flight Structures |

|

MIL-M-3171 |

Magnesium alloy, processes for pretreatment and prevention of corrosion |

Military |

|

MIL-S-13165 |

Shot peen of metal parts |

Military |

|

MIL-STD 1504 |

Abrasive blast |

Military |

|

PCS2300 |

Steel shot peening |

Safran |

|

DMP28 |

Surface compressive stressing |

Safran |

|

POP315-AC |

Wet abrasive blasting |

Pratt and Whitney |

|

POP317-N |

Glass bead wet blasting |

Pratt and Whitney |

|

POP338-N |

Cleaning weldable aluminium alloys |

Pratt and Whitney |

|

POP347-AF |

Cleaning of scale and rust from steel |

Pratt and Whitney |

|

POP350-AG |

Cleaning/degreasing of Parts |

Pratt and Whitney |

|

POP357-K |

Abrasive blast cleaning of steel or nickel alloy parts prior to aluminium spraying of ceramic coating |

Pratt and Whitney |

|

POP372-T |

Cleaning aluminium alloys before welding |

Pratt and Whitney |

|

POP390-M |

Cleaning aluminium alloys prior to brazing or welding |

Pratt and Whitney |

|

POP392-AR |

Wet glass bead peening to PWA 36906 |

Pratt and Whitney |

|

RPS386 |

Abrasive blasting |

Rolls-Royce |

|

RRP56001 |

Abrasive blasting |

Rolls-Royce |

|

SPOP16 |

Wet glass bead blast cleaning |

Pratt and Whitney |

|

SPOP209 |

Degreasing of parts by aqueous cleaning |

Pratt and Whitney |

|

SPOP212 |

Cleaning titanium parts before stress relief |

Pratt and Whitney |

|

SPOP215 |

Carbon seal cleaning |

Pratt and Whitney |

|

SPOP219 |

Wet abrasive blast with aluminium oxide and Novaculite |

Pratt and Whitney |

|

SPOP251 |

Removal of paint or varnish from aluminium parts |

Pratt and Whitney |

|

SPOP260 |

Removal of paint or varnish from aluminium, magnesium, steel, nickel and cobalt alloy parts |

Pratt and Whitney |

|

SPOP3 |

Vapor degreasing |

Pratt and Whitney |

|

SPOP500 |

Bead peening |

Pratt and Whitney |

|

PS12040 |

Abrasive cleaning |

Boeing Douglas |

|

PS211600 |

Cleaning of aluminium alloys |

Israeli Air |

|

PS5210 |

Abrasive blasting of composite propeller blades |

Dowty |

|

PS8 |

Cleaning and surface preparation of metallic materials |

Dowty |

|

PS95 |

Glass bead peening |

Dowty |

|

PS143 |

Abrasive blasting of metallic materials |

Dowty |

|

PS215 |

Aqueous cleaning |

|

|

RPS15.51 |

Abrasive blast cleaning |

Goodrich Aerostructures |

|

RPS15.52 |

Cleaning of aluminium |

Goodrich Aerostructures |

|

RPS15.53 |

Aqueous degreasing |

Goodrich Aerostructures |

|

SOPM20-10- 03 |

Shot peening |

Boeing (or MRO check?) |

|

SOPM20-10- 10 |

Shot peen |

Boeing |

|

SOPM20-30- 02 |

Stripping of protective finishes |

Boeing |

|

SOPM20-30- 03 |

General cleaning procedures |

Boeing |

|

SOPM20-60- 02 |

Finishing materials |

Boeing |

|

SPS-104080 |

Vapor degreasing |

Spirit |

|

SPS-107250 |

Stripping of coatings |

Spirit |

|

SPS-107480 |

Abrasive cleaning, deburring, and finishing |

Spirit |

|

SPS-107650 |

Cleaning and deoxidizing of aluminium alloys |

Spirit |

|

SS8787 |

Stripping of organic materials by plastic media blast method |

Sikorsky |

|

TPS06 |

Surface preparation |

TTF-Aircraft |

|

VPS31.02 |

Cleaning processes for aluminium and aluminium alloys |

Viking |

|

VPS31.07 |

Cleaning and stripping of painted surfaces |

Viking |

|

VPS33.02 |

Removal of metallic coatings |

Viking |

|

SPS-107250 |

Stripping of coatings |

Spirit |

|

SPS-107480 |

Abrasive cleaning, deburring, and finishing |

Spirit |

|

SPS-107650 |

Cleaning and deoxidizing of aluminium alloys |

Spirit |

|

SS8787 |

Stripping of organic materials by plastic media blast method |

Sikorsky |

|

TPS06 |

Surface preparation |

TTF-Aircraft |

|

VPS31.02 |

Cleaning processes for aluminium and aluminium alloys |

Viking |

|

VPS31.07 |

Cleaning and stripping of painted surfaces |

Viking |

|

VPS33.02 |

Removal of metallic coatings |

Viking |

Contact us to discuss how we can help you meet any of the specifications above