Nothing illustrates how Vapormatt wet-blasting can improve the surface finishing of your products like our sample processing service.

It also confirms you’re making the right decision because the full, detailed report – plus the sample processed components you receive back from us – reflect the ongoing quality and productivity you can expect from your Vapormatt wet-blasting system.

This is how it works: once agreed, you send us your samples and detailed written requirements. We then use the appropriate R&D wet-blasting system to produce a recipe and the perfect finish. That surface finish could include one or more of the following:

A minimum cost is charged for this service and is dependent on the number of samples and if a full detailed report is required.

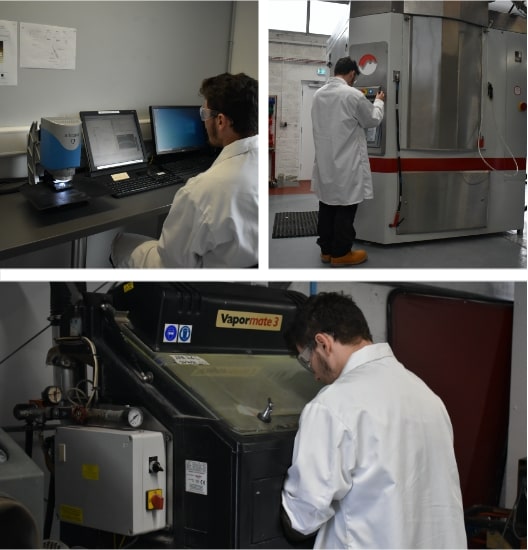

Based in Guernsey, our Research & Development centre is very well equipped with the following wet-blasting systems:

And the following measuring equipment:

We also have a range of highly specialised equipment, like our wire/bandsaw pulling rig, which allows us to accommodate a variety of existing and potential new applications.

We can carry out sample processing on most parts from most markets – our highly experienced R&D team regularly processes many different products and components.

Sample processing is often a key step in helping a company achieve its objectives. Often, it has led to the complete transformation of businesses thanks to massive improvements in product quality, productivity and, of course, ROI.