Automatic Machines

Our range of automatic wet blasting machines offers industry leading repeatability and process control for the same finishing results ever time with the addded benefit of improved productivity

Our range of automatic and manual wet blasting machines are designed for numerous different applications in multiple different industries. For a brief summary of the differences between automatic and manual wet blasting machines visit our 'What is wet blasting' page.

As well as browsing our ranges of automatic and manual wet blasting machines, scroll down for links, you can also find answers to the following:

Our range of automatic wet blasting machines offers industry leading repeatability and process control for the same finishing results ever time with the addded benefit of improved productivity

Ranging in size from the popular and compact Vapromate to the Puma XL, our manual wet blasting machines are built to last and are fully featured to ensure outstanding process control.

Contact us to discuss your wet blasting machine requirements

As original innovators of the first wet blasting machine, learn more about our history, we’ve remained global leaders in wet blasting technology thanks to our continued investment in R&D and our focus on the technology.

We’re trusted by leading manufacturers in numerous different industries including aerospace, automative, medical and tooling. Here’s why:

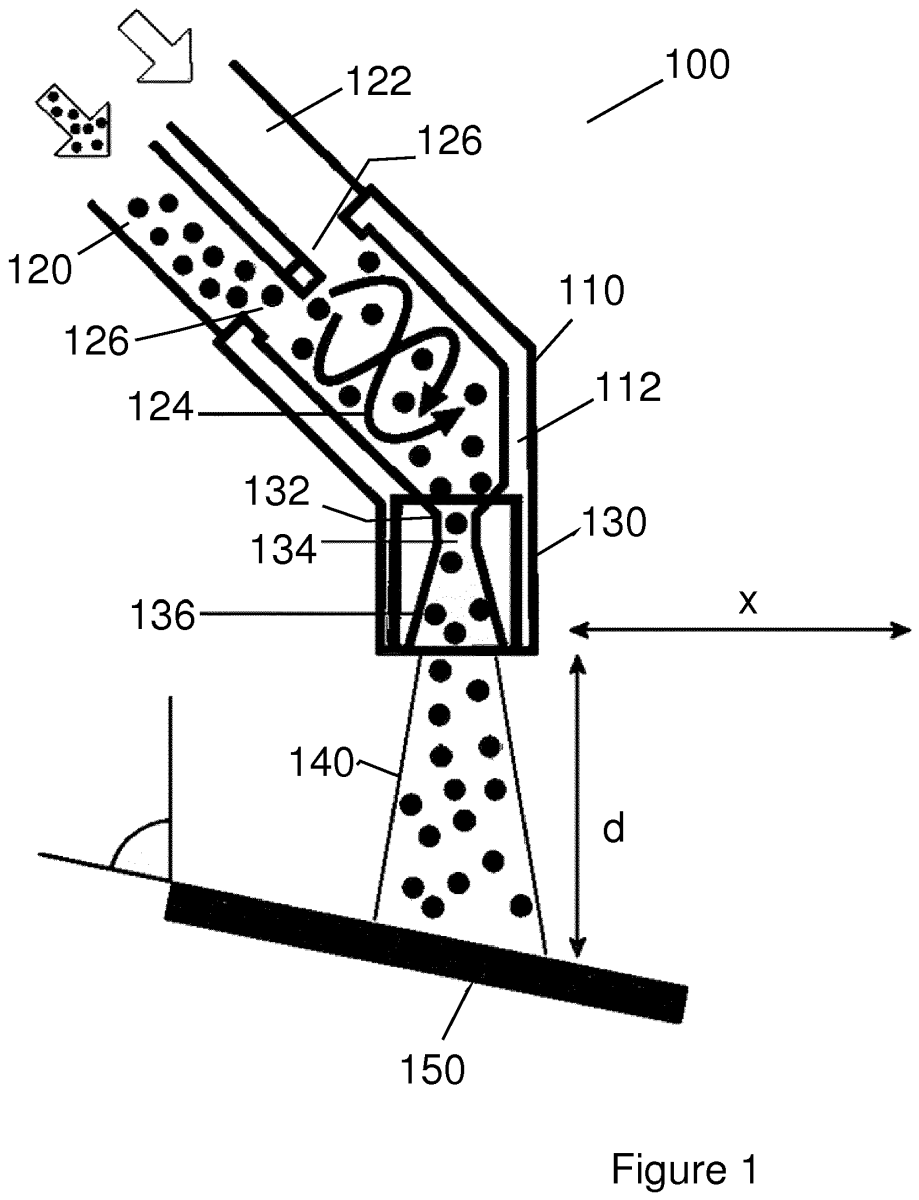

Industry leading surface finishing - Vapormatt machines deliver an exceptionally uniform and controlled finish, a level of precision many competitors struggle to achieve. That’s thanks to our unparalleled ability to control the wet blasting process, particularly when it comes to the flow of blast media slurry from our blast guns. Learn more about our control and automation

Patented technology – We’ve taken out a number of patents over the years to ensure the performance of our wet blasting machines lead the world. These range from our blast gun design to our elutriation tower that ensures only good blast media remains in a machine’s system without the use of sieves, which are prone to blocking. Learn more about our patents

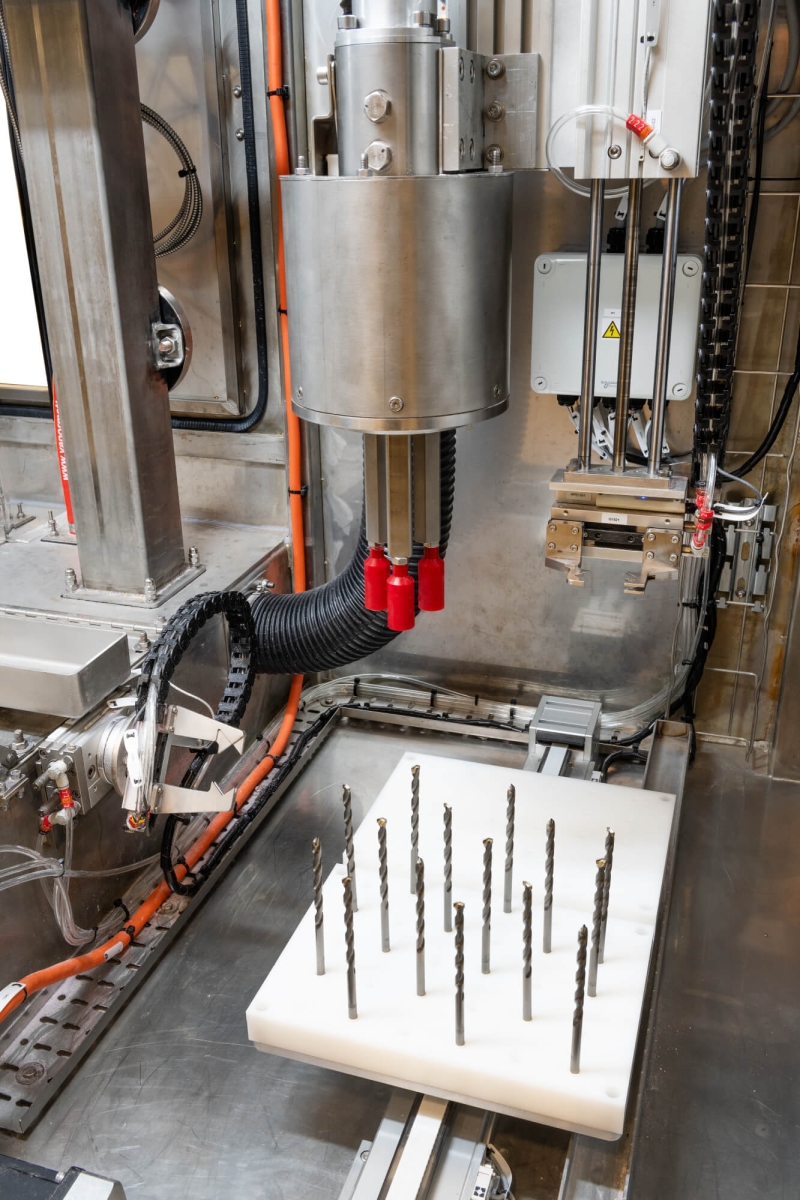

Automation and robotics capabilities – We have decades worth of experience in wet blasting automation. Today, our automatic machines make use multi-axis robotic arms and cartesian robots to ensure a perfect finish every time. Learn more about our automation

More efficient and cost-effective – Thanks to our superior wet blast slurry management, our machines use less abrasive media. All our machines are built for easy maintenance, and thanks to high-quality and durable components, maintenance costs are generally lower too. The closed loop filtration system on our machines results in reduced water consumption and waste disposal costs.

Superior build quality and durability - Vapormatt machines are designed for industrial environemtns and longevity, with stainless steel cabinet construction and high-grade components. We're still servicing Vapormatt machines that were built in the 1980's.

Trusted by industry leaders – We have a long and proven track record with some of the largest manufacturers in tooling, aerospace, medical, wire and cable, composites, additive manufacturing, and defence. Learn more about the industries we serve

Better after-sales support and expertise - We provide exceptional customer support globally and with the introduction of Vapormatt 4.0, our own Industry 4.0 solution, we can now offer preventative maintenance too. Vapormatt 4.0 is fitted to all new Vapormatt automatic machines. We also hold an extensive stock of spare parts for our own and competitor machines, and thanks to our our decades of technical expertise in wet blasting technology in multiple different industries, we can upgrade not only our own machines with the latest wet blasting technology but competitor machines too. Learn more about our aftermarket services

Comprehensive range – We only sell wet blasting machines, so that not only means our knowledge and expertise of wet blasting is second to none, but our range of automatic and manual wet blasting machines is the most comprehensive too. This helps ensure we have a perfect solution for all applications in the industries we serve. Browse our comprehnesive range of automatic and manual wet blasting machines

Contact us to discuss the advantages of our wet blasting machines

Buying a wet blasting machine depends on your needs, budget, and intended application. Here’s a step-by-step guide to help you find the best option:

1. Identify your requirements

2. Set a budget

3. Compare features

For example:

4. Evidence that your components can be processed successfully

5. Buy from a reputable manufacturer or distributor

6. Consider financing options

Contact us to discuss any of the points above

Test processing sample components might be necessary if:

Learn more about sample processing and the equipment we have at our R&D centre

Contact us to discuss your sample processing requirements

We recognise that the initial cost and on-going costs of a wet blasting machine need careful consideration, that’s why we offer purchase, rental, lease, lease +, contract and contract + options to make ownership as easy and straight forward as possible.

Learn more about the different ownership options we offer

Contact us to discuss the different ownership options we offer

We often have a range of refurbished machines in stock and the occassional ex-demo macine. Visit our refurbished machine page to see what’s available. Contact our us, link below, if nothing suitable is shown as we may have machines that haven't been posted on-line yet.

You can also contact us to find out:

Special rental deals from £10 per day

Where necessary, machines have been converted to include our non-blocking abrasive delivery system bringing them up to date and easy to use.

If a machine is have been marked 'Vapormatt Inside' then it has been refurbished with Vapormatt components to improve its performance. There is also the option to refurbish your existing system via our 'Vapormatt Inside' service.

All Vapormatt refurbished machines come with a 12 Month Guarantee.

Contact us to discuss your refurbished machine requirements

Thanks to our extensive expertise we can not only upgrade your existing Vapormatt wet blasting machine 'Vapormatt upgrade' to suit your production requirements, but we can also upgrade competitor machines too 'Vapormatt Inside.'

Visit our Vapormatt inside and upgrade page to learn more

Contact us to discuss your upgrade requirements

Vapor blasting machine, vapour blasting machine, slurry blasting machine, aqua blasting machine, hydro blasting machine, liquid honing machine, water abrasive blasting machine, wet sandblasting machine, water media blasting machine, dustless blasting machine and abrasive water blasting system are all alternative names for a wet blasting machine.

Learn what wet blasting is and how it works

Contact us to discuss your wet blasting machine requirements

We offer extensive industry leading support for our customers with our range of service contracts, repairs, spare parts for our own and competitor machines and we can even upgrade your existing Vapormatt wet blasting machine or a competitor’s machine to meet your new production requirements.

Contact us to discuss your aftermarket needs