We have a long-established heritage of supplying wet blasting solutions to the world’s largest aerospace engine manufacturers. Our association with the industry began with the invention of the first wet blasting machine, while exploring surface treatments with Sir Frank Whittle during the development of the jet engine. Learn more about our history.

To this day world leading aerospace engine manufacturers trust us and our well proven wet blasting technology for their finishing requirements.

Wet blasting (also known as vapor blasting, or aqua blasting) has numerous applications and benefits for a wide range of other aerospace components too.

Sir Frank Whittle inventor of the turbojet engine

Click on the subject relevant to your manufacturing operation to learn about the associated wet blasting applications and benefits.

CONTACT US IF YOU ALREADY KNOW YOUR WET BLASTING REQUIREMENTS

At a glance...

| Applications | Peening for improved strength whilst producing a high-quality surface finish |

| Components | Fan, turbine and compressor blades, engine shafts, discs, blisks, engine casings, landing gear |

| Key Benefits | Shot peening to the same intensity as dry shot peening whilst producing a superior surface finish |

| Machines | Leopard, Leopard Cub, Sabre |

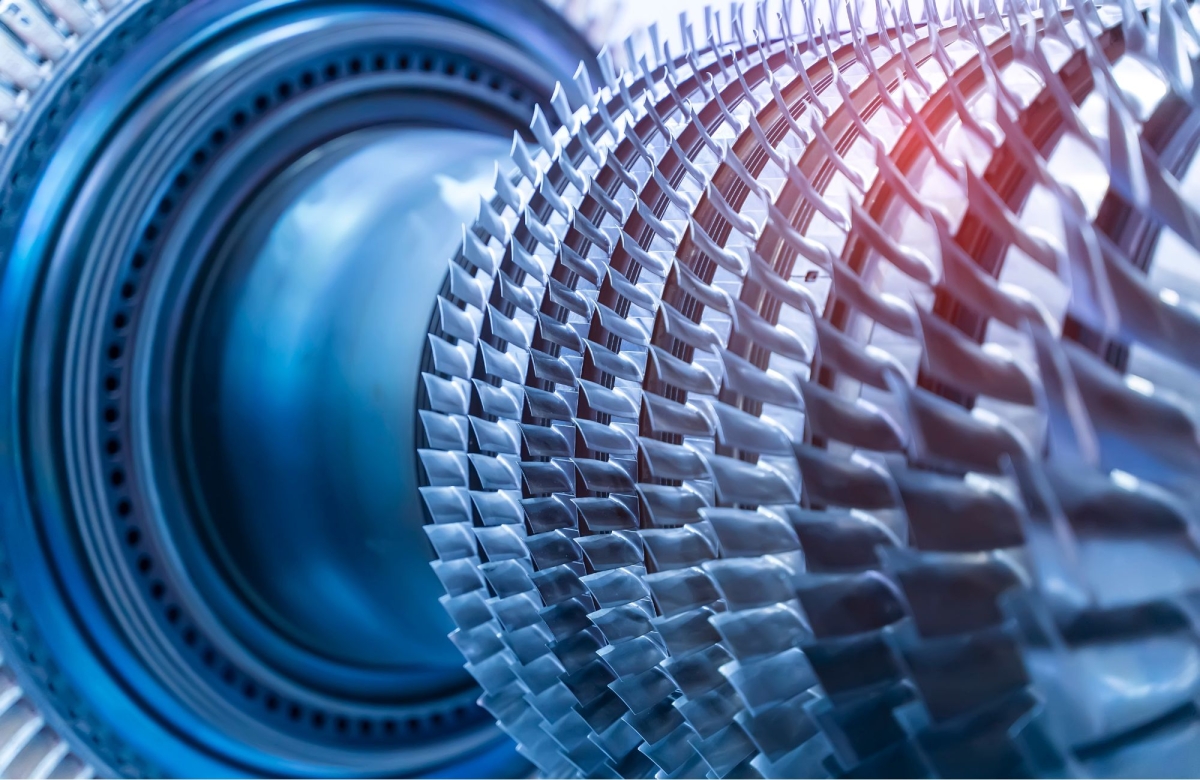

Cross section of a turbofan jet engine

The lifespan of a turbine blade can be extended dramatically by wet shot peening – more than 1000%. The process involves projecting a mixture of water and small hard spherical media particles at turbine blades, fan blades, blisks, discs, driveshafts and any other engine components that need strengthening. It is a highly effective way to improve fatigue strength.

As well as peening to the same intensity as dry blasting, the flow of media over components ensures a smoother, more consistent, and higher quality finish compared with dry shot peening.

By bombarding the engine component with the peening blast media, the substrate is exposed to compressive stresses that improve strength by giving the grain structure a shallower depth with a more random texture pattern. This change to a surface’s structure through peening makes it far less likely to fracture and crack.

Typically peening is used on components that are irregular in shape and that may be subject to twisting and bending stresses. Users of the wet peening process on components like these have recorded significantly increased product life and quality across a range of industries, including jet engine manufacturing.

Jet engine internal structure

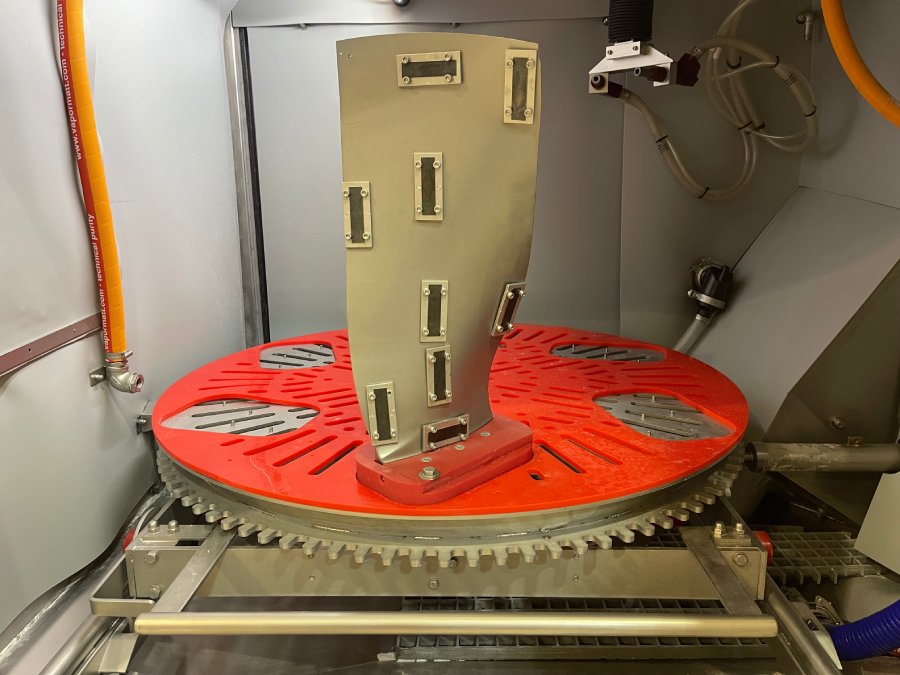

Aerospace fan blade with Almen Strips

We state above that wet shot peening peens to the same intensity as dry shot peening. We measure this using Almen strips, which are thin strips of SAE 1070 steel used to quantify the intensity of the shot peening process.

The strips are placed on the component where the results are deemed critical. As you can see from the image opposite, that is in quite a few places when it comes to jet engine fan blades.

The peening process converts tensile stresses to compressive stresses causing the strip to deform into an arch. The resulting arch is concave, the opposite to what you might counter intuitively think until you realise the compressive stresses created cause the steel to bow upwards towards the direction of the arch.

The degree of arching is measured using a gauge and that is how we know wet shot peening has peened to the same intensity as dry shot peening.

Wet shot peening meets or helps meet the requirements for the following industry specifications, amongst others:

| Document Number | Document Title | Manufacturer |

| AMS 2432 | Shot peening, computer-controlled | Multiple OEMs |

| POP 392-AR | Wet glass bead peening to PWA 36906 | Pratt and Whitney |

| RPS 428 | Controlled blasting and peening for fatigue resistance | Rolls-Royce |

| P11TF8 | Metallic shot peening | GE |

| DMP28 |

Surface compressive stressing |

SNECMA / Safran |

| 32-09-01 | Glass bead peening of light alloy parts | Safran |

See the full list of specifications our wet blasting technology can help you achieve.

CONTACT US TO DISCUSS YOUR WET SHOT PEENING REQUIREMENTS

At a glance...

|

Applications |

Creating ‘wet-out’ surfaces on composite components for bonding and coating |

| Components |

Fan blades, propeller blades, helicopter blades and other composite aerospace components |

|

Key Benefits |

The ‘wet-out’ surface ensures consistent and thorough coverage of adhesives or coatings for maximum bond strength |

| Machines |

Leopard, Leopard Cub, Sabre, Lion Rotary |

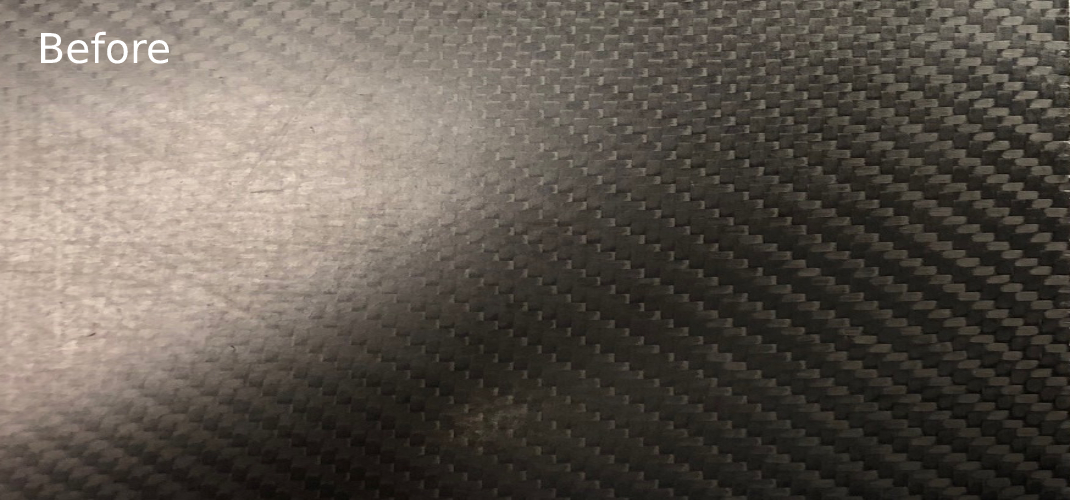

Composite fan blades

Wet blasting is highly effective at cleaning and preparing composite fan blades, propeller blades, helicopter blades and other aerospace composite components for bonding and coating.

The wet blasting process thoroughly cleans the component, removing waxy residues and other contaminants that might have a negative effect on adhesion. Simultaneously, the process creates a consistent ‘wet-out’ surface that allows an even and complete coverage of adhesives or coatings, e.g. paint, over the processed area.

Thorough cleaning and the creation of a ‘wet-out’ surface helps ensure bond strength is maximised, which is critial for bonding titanium leading edges to fan blades or heater mats to propeller and helicopter blades for example.

The cushioning effect of the water in wet blasting means composite fibres are not damaged during blasting. There is no material loss from the component either, so any potential compromise to the component’s integrity is eliminated.

The improvement in bond strength is applicable to all coatings, not just adhesives, so the adhesion of paint, lacquers, and other coatings, is optimised too.

To learn more about wet blasting composites visit our composites industry page, where you will be able to see a video of a ‘wet-out’ surface being created and the effect it has.

Turboprop aircraft engine propeller

CONTACT US TO DISCUSS YOUR PREPARATION FOR COMPOSITE BONDING REQUIREMENTS

At a glance...

|

Applications |

Thoroughly cleaning components for NDT crack detection |

| Components |

Fan, turbine and compression blades, blisks, hubs / discs, drive shafts, struts, wheels and just about any component that needs inspecting |

|

Key Benefits |

Removes all contaminants and does not peen over cracks, instead cracks are cleaned out so they are more visible |

| Machines |

Leopard, Leopard Cub, Lion Rotary, Sabre, Puma |

The ‘fir tree’ slots of a turbine blade disc

Wet blasting thoroughly cleans components, removing burrs, debris, and other contaminants in preparation for NDT crack detection. Crucially, there is no danger of peening over cracks during the cleaning operation, instead the flowing nature of the wet blast slurry exposes cracks by cleaning them rather than concealing them, making them more visible during NDT – improving inspection accuracy, speed, and subsequent safety.

Discs, driveshafts, turbine and fan blades, blisks, titanium engine casings, wheels, struts and a broad range of other aerospace components can be cleaned using wet blasting, with no risk of damage to the component or any risk of compromising the component’s integrity.

Wet blasting for inspection differs to wet shot peening, see the section above, in terms of the wet blast recipe used. The wet blast recipes associated with NDT crack detection consist of a blast medias and flow rates that do not peen.

Note that preparation for NDT is similar for both MRO and OEM operations.

CONTACT US TO DISCUSS YOUR PREPARATION FOR NDT REQUIREMENTS

|

Applications |

Prepares surfaces for coating, including CVD and PVD coating |

| Components |

Fan, turbine and compression blades, blisks, hubs / discs, drive shafts, struts, wheels and just about any component that needs coating |

|

Key Benefits |

Cleans, removing all contaminants, and creates a surface that is perfect for bonding and coating in one operation |

| Machines |

Leopard, Leopard Cub, Lion Rotary, Sabre |

Coated turbine blades

PVD or CVD coating fan blades has two important affects. First, it maintains the surface finish of the blade for much longer by significantly reducing wear. Second, coatings make the surface finish smoother for better fuel efficiency.

Aerospace engine components operate in extreme conditions, so the bond strength of coatings like PVD and CVD needs to be maximised.

Wet blasting is highly effective at producing the perfect surface finish on blades and other aerospace components for coating. It does this by creating a specific Ra surface roughness for the best possible coverage and adhesion of coatings.

CONTACT US TO DISCUSS YOUR PREPARATION FOR COATING REQUIREMENTS

|

Applications |

Cleans and finishes metal, composite and polymer additive manufactured components |

| Components |

Any additive manufactured component |

|

Key Benefits |

Cleans, removing all imperfections, build lines and sinter powder from internal channels, whilst applying a final finish or a finish that is perfect for coating or bonding |

| Machines | Leopard, Leopard Cub, Lion Rotary, Sabre, Puma |

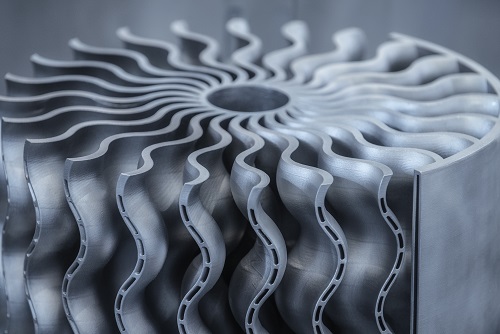

AM printed aircraft engine component

Thanks to advances in additive manufacturing (AM), a significant number of aerospace components are now manufactured using AM technologies. Wet blasting is highly suited to cleaning and preparing metal, composite, and polymer AM aerospace components for NDT or coatings like paints and oils.

It is also particularly effective at clearing powder, partially sintered powder, and other contaminants from the complex internal channels that are often a feature of AM components, giving a visual indication that the channel is clear when the wet blast slurry appears.

In contrast, it is not only difficult to tell if a channel is clear when dry blasting, it can even compound the issue by adding additional blast media to blocked channels.

CONTACT US TO DISCUSS YOUR AM COMPONENT FINISHING REQUIREMENTS

At a glance...

|

Applications |

Cleaning, removing casting resist, burrs, heat scale, and other contaminants, applying a specific surface finish |

| Components |

Fan, turbine and compressor blades, blisks, discs, drive shafts, nozzle guide vanes, titanium engine casings, landing struts, and other cast components |

|

Key Benefits |

Rapid, dust free operation, cleaning and surface finishing in one operation |

| Machines |

Leopard, Leopard Cub, Lion Rotary, Sabre, Puma |

Wet blasting is highly effective at removing casting resist, burrs, heat scale and other contaminants from the surfaces of fan and turbine blades, blisks, drive shafts, nozzle guide vanes, titanium engine casings, landing struts and other components manufactured by investment casting.

In addition to cleaning components, the process can also apply the final surface finish required, or prepare the component for the next surface finishing stage.

The removal of casting resist and burrs, cleaning, and applying a surface finish is carried out in one efficient operation.

Cast engine component

CONTACT US TO DISCUSS YOUR WET BLASTING REQUIREMENTS FOR CAST COMPONENTS

At a glance...

|

Applications |

Cleaning, removing heat scale, oxidation and machining marks, applying a specific surface finish |

| Components |

Engine shafts, compressor discs, turbine discs, rings and casings, landing gear, and other forged components |

|

Key Benefits |

Rapid, dust free operation, cleaning and surface finishing in one operation |

| Machines |

Leopard, Leopard Cub, Lion Rotary, Sabre, Puma |

Aircraft landing gear

The forging process for components like landing gear struts and beams often results in the presence of heat scale and oxidation on the component’s surface, this is also the case for components manufactured by other thermal processes.

In a single efficient operation, wet blasting removes all heat scale, oxidation, machining marks, and other contaminants, cleans the component, and applies the required uniform surface finish to meet stringent aerospace industry standards.

Wet blasting is also highly effective at reaching into small cavities and complex geometries, ensuring thorough cleaning.

The finish applied can either be the final surface finish or the finish required for the next surface finishing stage. For example, the process creates an ideal surface profile for subsequent coating applications, such as paint, anodizing, or thermal spray coatings, by promoting better adhesion and coating uniformity.

CONTACT US TO DISCUSS YOUR WET BLASTING REQUIREMENTS FOR FORGED COMPONENTS

_______________________________________________________________

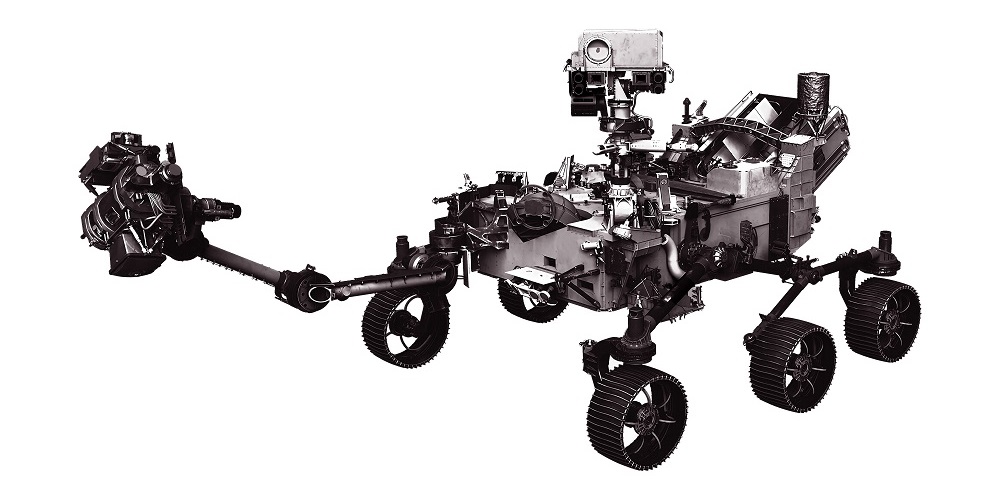

Cutting inserts fitted to the Mars Rover’s drill were finished in a Vapormatt Tiger

Exceptional levels of process control, highly uniform finishing, excellent repeatability and all the other benefits associated with wet blasting make it the ideal finishing process for components destined for space.

Our unrivalled expertise in maintaining a consistent blast flow coupled with automation ensures we can repeatedly deliver a highly consistent Ra surface roughness to component surfaces.

The Ra level of surface roughness can be set to a range, typically between 0.25 and 0.6 µm, that is perfect for sterilisation. Less than 0.25 µm Ra is suboptimal as microbes can effectively 'stick' to the surface and above 0.6µm Ra creates a larger surface area for microbes to populate.

Wet blasting is also ideal for preparing components for coatings, including adhesives and paint. This includes composite and additive manufactured components. The cushioning effect of water in the wet blast process ensures there is no material loss, so the integrity of the component is never compromised.

All of these factors contribute to the safety and reliability of components destined for space.

Controlling what comes out of the blast guns is essential for high quality consistent results. That applies to all applications, from cleaning and wet shot peening to surface preparation.

It is particularly important for automatic processes where the operator is not always there to visually check the consistency of blast flow and the results.

Vapormatt are second to none when it comes to controlling the consistency of output from blast guns.

The blast flow must always remain consistent and thanks to our world leading technical expertise and our patented technology we can achieve a consistent flow year in year out without change, even when components start to wear in the normal course of operation.

See our case study ‘Preparation of jet engine compressor hubs for NDT by wet blasting’ toward the bottom of our Aerospace MRO page for a detailed explanation of how our ability to control the consistency of blast combined with our ability to accurately position blast guns significantly increases productivity and finish quality when processing turbine discs and other engine components.

Our unrivaled ability to control the consistency of blast is present throughout our machine range.

Watch our video on the controllable factors of wet blasting and how we control them...

CONTACT US TO DISCUSS OUR WORLD LEADING WET BLASTING CONSISTENCY AND ACCURACY

The accurate positioning of blast guns is another critical element associated with high quality consistent results. Our robotic automation can be programmed to accurately blast at multiple indexing points. If required, the blast guns can be moved by as little as 0.5mm.

This degree of accuracy is perfect for blasting highly complex components like the individual slots and angles associated with the ‘fir trees’ of a turbine disc.

Automation also ensures exactly the same blast recipe is delivered evenly to the entire surface of the component every time, making it ideal for finishing batches of the same component.

CONTACT US TO DISCUSS OUR WORLD LEADING WET BLASTING CONSISTENCY AND ACCURACY

There are several additional benefits our customers have experienced when wet shot peening aerospace fan and turbine blades compared with legacy dry shot peening systems, including:

CONTACT US TO DISCUSS ANY OF THE POINTS ABOVE THAT ARE RELEVANT TO YOUR MANUFACTURING OPERATION

Overall, wet blasting offers aerospace manufacturers a highly versatile and efficient solution for cleaning, surface preparation and peening, helping to ensure components are safe, reliable, and perform as well as they can do.

Read our case studies to find out how our wet blasting machines are helping aerospace organisations with their manufacturing requirements. Read our white papers for a deep dive into specific manufacturing applications.

Explore our automatic and manual wet blasting machines section below to gain a better understanding of what our machines can do. Videos, technical specifications, images, etc. are available for each wet blasting machine (also known as vapor blasting machine, vapour blasting machine and aqua blasting machine).

CONTACT US TO DISCUSS HOW OUR WET BLASTING TECHNOLOGY CAN HELP YOUR MANUFACTURING OPERATION

Our wet blasting technology can help support the following requirements of the following specifications

|

Aerospace specifications our wet blasting can help support Our wet blasting technology can help support the following requirements of the following specifications |

||

|

Document Number |

Documents Title |

Airframe Manufacturer |

|

208-13-40 |

Shot and glass bead peening |

Triumph Vought |

|

208-9-146 |

Aqueous degreasing |

Triumph Vought |

|

ABP1-2028 |

Shot peening for improved fatigue and stress corrosion resistance |

Airbus |

|

ABP1-2344 |

Cleaning and surface improvement blasting |

Airbus |

|

ABP5-1351 |

Surface preparation prior to application of paints |

Airbus |

|

ABP8-1290 |

Cleaning and degreasing of metallic materials |

Airbus |

|

ABP8-1294 |

Cleaning & degreasing of metallic materials |

Airbus |

|

ABP8-1296 |

Deoxidation of aluminium alloys |

Airbus |

|

AIPS02-02- 003 |

Wet blasting |

Airbus |

|

AMS-S 13165 |

Shot peening of metal parts |

Multiple OEM's |

|

AMS2430 |

Shot peening |

Multiple OEM's |

|

AMS03-2 |

Cleaning and preparation of metal surfaces |

Multiple OEM’s |

|

ASTM-B-600 |

Descaling and cleaning titanium and titanium alloy surfaces |

Multiple OEM's |

|

BAC5730 |

Shot peening |

Boeing |

|

BAC5751 |

Cleaning, descaling and surface preparation of ferrous alloys |

Boeing |

|

BAC5753 |

Cleaning, descaling and surface preparation of titanium and titanium alloys |

Boeing |

|

BAC5758 |

Cleaning, descaling and surface preparation of nickel and cobalt base alloys |

Boeing |

|

BAC5765 |

Cleaning and deoxidizing aluminium alloys |

Boeing |

|

BAC5769 |

Cleaning, descaling and surface preparation of magnesium alloys |

Boeing |

|

BAC5770 |

Cleaning, descaling and surface preparation of Boeing copper alloys |

Boeing |

|

BAC5771 |

Stripping inorganic finishes |

Boeing |

|

BAC5951 |

Glass bead peening (S/S by BAC5730) |

Boeing |

|

BAPS 180- 007 |

Vapour degreasing |

Bombardier |

|

CSFS037 |

Abrasive cleaning of metals |

Cessna |

|

CSFS040 |

Paint stripping |

Cessna |

|

CSFS042 |

Vapor degreasing |

Cessna |

|

CVA13-1 |

Blast Cleaning of Metal Parts |

Triumph Vought |

|

CVA9-17 |

Treatment of metallic surfaces for paint adhesion |

Triumph Vought |

|

DPS4.999 |

Shot peening of metal parts |

Douglas |

|

DPS9.014 |

Cleaning copper and copper Alloys |

Douglas |

|

DPS9.05 |

Cleaning of carbon steels and low alloy steels |

Douglas |

|

DPS9.301 |

Cleaning aluminium alloys |

Douglas |

|

DPS9.341-1 |

Aqueous degreasing |

Douglas |

|

FSI-PS-4020 |

Cleaning of aluminium, steel and cres |

Flight Structures |

|

MIL-M-3171 |

Magnesium alloy, processes for pretreatment and prevention of corrosion |

Military |

|

MIL-S-13165 |

Shot peen of metal parts |

Military |

|

MIL-STD 1504 |

Abrasive blast |

Military |

|

PCS2300 |

Steel shot peening |

Safran |

|

DMP28 |

Surface compressive stressing |

Safran |

|

POP315-AC |

Wet abrasive blasting |

Pratt and Whitney |

|

POP317-N |

Glass bead wet blasting |

Pratt and Whitney |

|

POP338-N |

Cleaning weldable aluminium alloys |

Pratt and Whitney |

|

POP347-AF |

Cleaning of scale and rust from steel |

Pratt and Whitney |

|

POP350-AG |

Cleaning/degreasing of Parts |

Pratt and Whitney |

|

POP357-K |

Abrasive blast cleaning of steel or nickel alloy parts prior to aluminium spraying of ceramic coating |

Pratt and Whitney |

|

POP372-T |

Cleaning aluminium alloys before welding |

Pratt and Whitney |

|

POP390-M |

Cleaning aluminium alloys prior to brazing or welding |

Pratt and Whitney |

|

POP392-AR |

Wet glass bead peening to PWA 36906 |

Pratt and Whitney |

|

RPS386 |

Abrasive blasting |

Rolls-Royce |

|

RRP56001 |

Abrasive blasting |

Rolls-Royce |

|

SPOP16 |

Wet glass bead blast cleaning |

Pratt and Whitney |

|

SPOP209 |

Degreasing of parts by aqueous cleaning |

Pratt and Whitney |

|

SPOP212 |

Cleaning titanium parts before stress relief |

Pratt and Whitney |

|

SPOP215 |

Carbon seal cleaning |

Pratt and Whitney |

|

SPOP219 |

Wet abrasive blast with aluminium oxide and Novaculite |

Pratt and Whitney |

|

SPOP251 |

Removal of paint or varnish from aluminium parts |

Pratt and Whitney |

|

SPOP260 |

Removal of paint or varnish from aluminium, magnesium, steel, nickel and cobalt alloy parts |

Pratt and Whitney |

|

SPOP3 |

Vapor degreasing |

Pratt and Whitney |

|

SPOP500 |

Bead peening |

Pratt and Whitney |

|

PS12040 |

Abrasive cleaning |

Boeing Douglas |

|

PS211600 |

Cleaning of aluminium alloys |

Israeli Air |

|

PS5210 |

Abrasive blasting of composite propeller blades |

Dowty |

|

PS8 |

Cleaning and surface preparation of metallic materials |

Dowty |

|

PS95 |

Glass bead peening |

Dowty |

|

PS143 |

Abrasive blasting of metallic materials |

Dowty |

|

PS215 |

Aqueous cleaning |

|

|

RPS15.51 |

Abrasive blast cleaning |

Goodrich Aerostructures |

|

RPS15.52 |

Cleaning of aluminium |

Goodrich Aerostructures |

|

RPS15.53 |

Aqueous degreasing |

Goodrich Aerostructures |

|

SOPM20-10- 03 |

Shot peening |

Boeing (or MRO check?) |

|

SOPM20-10- 10 |

Shot peen |

Boeing |

|

SOPM20-30- 02 |

Stripping of protective finishes |

Boeing |

|

SOPM20-30- 03 |

General cleaning procedures |

Boeing |

|

SOPM20-60- 02 |

Finishing materials |

Boeing |

|

SPS-104080 |

Vapor degreasing |

Spirit |

|

SPS-107250 |

Stripping of coatings |

Spirit |

|

SPS-107480 |

Abrasive cleaning, deburring, and finishing |

Spirit |

|

SPS-107650 |

Cleaning and deoxidizing of aluminium alloys |

Spirit |

|

SS8787 |

Stripping of organic materials by plastic media blast method |

Sikorsky |

|

TPS06 |

Surface preparation |

TTF-Aircraft |

|

VPS31.02 |

Cleaning processes for aluminium and aluminium alloys |

Viking |

|

VPS31.07 |

Cleaning and stripping of painted surfaces |

Viking |

|

VPS33.02 |

Removal of metallic coatings |

Viking |

|

SPS-107250 |

Stripping of coatings |

Spirit |

|

SPS-107480 |

Abrasive cleaning, deburring, and finishing |

Spirit |

|

SPS-107650 |

Cleaning and deoxidizing of aluminium alloys |

Spirit |

|

SS8787 |

Stripping of organic materials by plastic media blast method |

Sikorsky |

|

TPS06 |

Surface preparation |

TTF-Aircraft |

|

VPS31.02 |

Cleaning processes for aluminium and aluminium alloys |

Viking |

|

VPS31.07 |

Cleaning and stripping of painted surfaces |

Viking |

|

VPS33.02 |

Removal of metallic coatings |

Viking |

Contact us to discuss how we can help you meet any of the specifications above