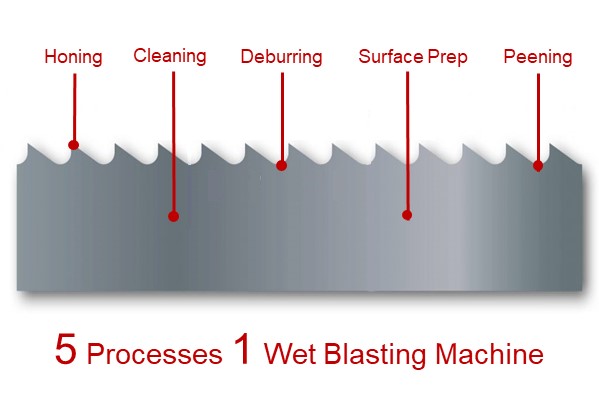

Our unique automatic Profelis wet blasting machine can perform the following processes on bandsaw blades:

• Honing - Wet blasting can accurately hone bandsaw blade cutting teeth to a specific radius, reducing heat build-up in the tips of the teeth and the likelihood of chipping, micro-cracking, or premature wear. This contributes to extended blade life and better performance. It also eliminates the need for the blade to be ‘worn in’, allowing it to be used at full production speed from new.

• Cleaning - Wet blasting removes contaminants like oils, dust, grease, and debris from the surface of blades. This is crucial for ensuring proper adhesion of any coatings subsequently applied to the blade’s surfaces.

• Deburring - Blades can often have sharp edges and burrs from the manufacturing process. Wet blasting removes these burrs and smooths out sharp edges, resulting in safer handling and potentially better cutting performance.

• Surface Prep. – Wet blasting produces a consistent, aesthetic, and uniform surface finish on blades. It creates a smoother and more polished surface compared to dry blasting, resulting in a blade with reduced roughness and improved aesthetics. The clean reactive surface created has an optimum surface roughness (Ra) for best possible coating adhesion. Coatings could range from oils to paints, including branding.

• Peening – Peening strengthens the gullet between the blade’s teeth, a common area of blade weakness. It significantly reduces tensile stress to help eliminate blade fatigue.