Vapormate - Our versatile entry level manual machine. With a generous working envelope, it’s popular with users who need a compact machine for smaller spaces. The Vapormate comes packed with all the features you would expect to find in our larger machines to ensure excellent process control and high-quality finishing.

Puma - With its large, wide opening door and working envelope, this manual machine is ideal for processing small to large sized composite components within a small footprint. It can also be fitted with an optional barrel for processing fixings and other smaller parts.

Puma XL - Our extra large manual wet blasting machine offers a very generous working envelope to accommodate larger composite components. The Puma XLs powerful and efficient pump ensures rapid processing.

Puma + Our entry-level automatic machine is popular with users who want to step up from a manual machine for the added productivity and repeatability automation offers. It can be fitted with an optional barrel for fixings and other smaller components and there is a vertical oscillating version for taller components like tools.

Cougar + Our highly versatile automated mid-range machine. It is a popular system with heavy users thanks to its durability, reliability, and repeatability of processing. The Cougar + can be fitted with a vertical oscillation for taller components like fan blades.

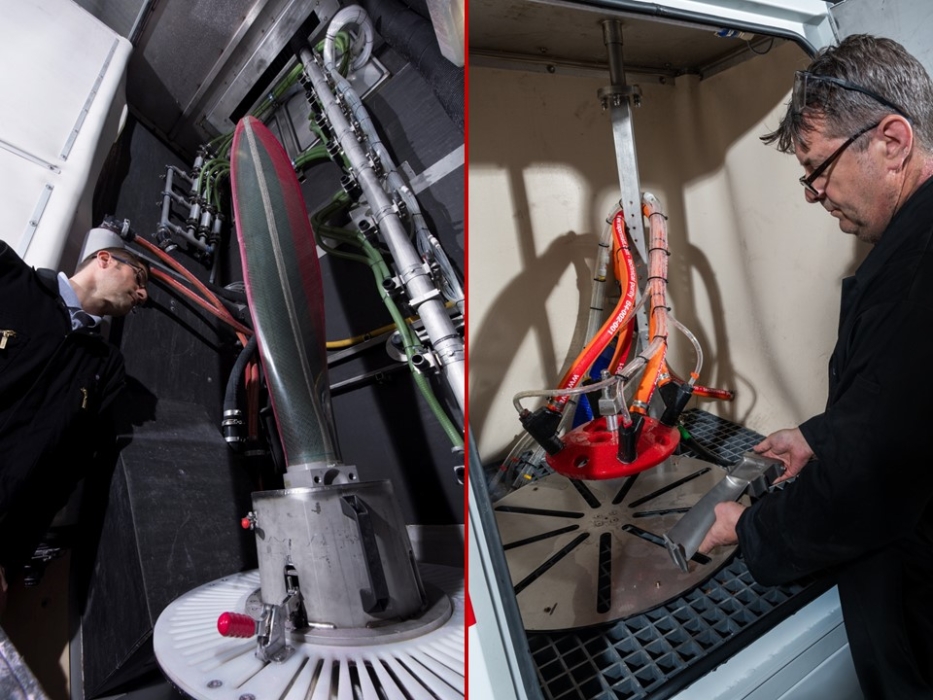

Sabre - The Sabre is a highly flexible and efficient system. Its cartesian robot can support multiple blast guns and provides 4 axis of movement. With 100 programmable coordinates, the point-to-point blasting is highly controlled and repeatable. Hubs, blisks, and fan blades are typically processed in it.

Leopard Vertical - This tall, automatic machine is well suited for fan blade, propeller blade and the finishing of other taller composite components. It is approved for use in the manufacturing of Trent Turbofan engines.

Leopard Horizontal - This machine offers a manual work station with separate automatic processing for the largest compost components and is used by engine shops to clean the General Electric GE9X Turbofan engine, amongst other applications.

Leopard Cub - Our most compact automated machine that can be configured with a cartesian or 6-axis robot. Amongst lots of other composite related applications, it is used extensively in wet shot peening applications for the cleaning of IAE rotor hubs.