Wet blasting is highly suited to cleaning, de-painting, and preparing metal, composite, and polymer AM aerospace components for NDT or coatings like paints and oils.

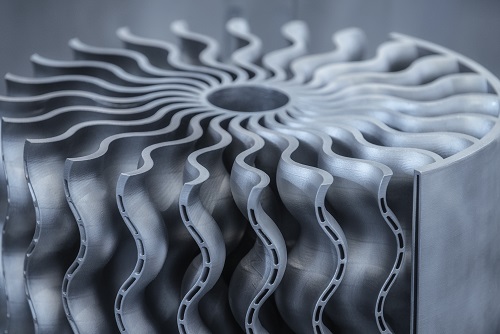

It is also particularly effective at clearing powder, partially sintered powder, and other contaminants from the complex internal channels that are often a feature of AM components, giving a visual indication that the channel is clear when blast media appears.

In contrast, it is not only difficult to tell if a channel is clear with dry blasting, it could even compound issues by adding additional blast media to blocked channels.

Wet blasting has significant HSE benefits over other processes, thanks to the lack of harmful chemicals and airborne dust, and the recirculation of water and blast media in the wet blast system.

Learn more