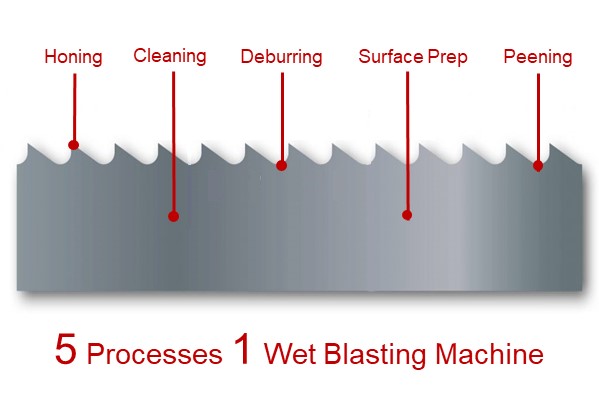

Vapormatt Profelis: 5 finishing processes for bandsaw blades, 1 wet blasting machine (also called vapor blasting machine, vapour blasting machine, aqua blasting machine) – When configured for bandsaw blades our automatic Profelis wet blasting machine can…

- Hone cutting teeth – Applying a small radius to cutting teeth dramatically reduces heat build-up and the likelihood of chipping

- Clean bandsaw blades - Removing oils, dust, debris and other contaminants

- Deburr – Blades often have sharp edges and burrs after manufacturing, wet blasting removes burrs and smooths sharp edges

- Prepare surfaces – Wet blasting produces an aesthetic uniform surface and / or a surface that’s the perfect Ra surface roughness for the adhesion of oils or branding

- Peen areas of weakness – The gullet between teeth is a known area of weakness on bandsaw blades, wet blasting strengthens the area to help eliminate blade fatigue