A common area of quality concern for round shank tools is the successful application of a durable PVD coating. A highly reactive tool surface helps ensure even coating application and strong coating adherence.

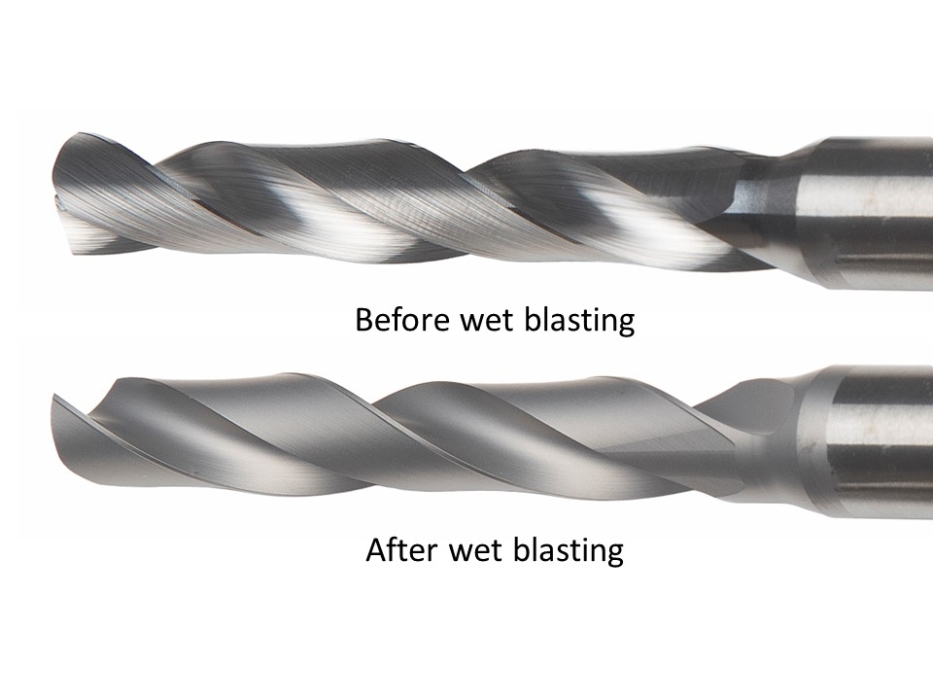

Wet blasting is exceptionally good at creating these reactive surfaces. Finishing surfaces to the specific Ra surface roughness that is perfect for the application of coatings.

Wet blasting after coating removes coating imperfections, like coating droplets, to leave a uniform surface with an optimum Ra surface roughness for the cutting operation required from the tool.

Coatings like PVD typically have an incumbent tensile stress that can reduce the durability of the coating. Wet blasting can be used to peen the coating, converting tensile stresses into compressive stresses and in turn, dramatically improving the durability of the coating.