Vapormatt has once again demonstrated its competence in systems design using a collaborative approach with 65 manufacturers across the globe. By designing and installing a system, that was a world first, for the removal of graphite lubricants from tool steel, clear benefits in terms of quality and speed have been realised.

As one of the world’s leading wet blasting companies Vapormatt were initially approached because of the environmental benefits of the Profelis wire cleaning system. The Vapormatt wet blast process uses a controlled mix of gas, air and solids that are inert and safe to use in all industrial environments.

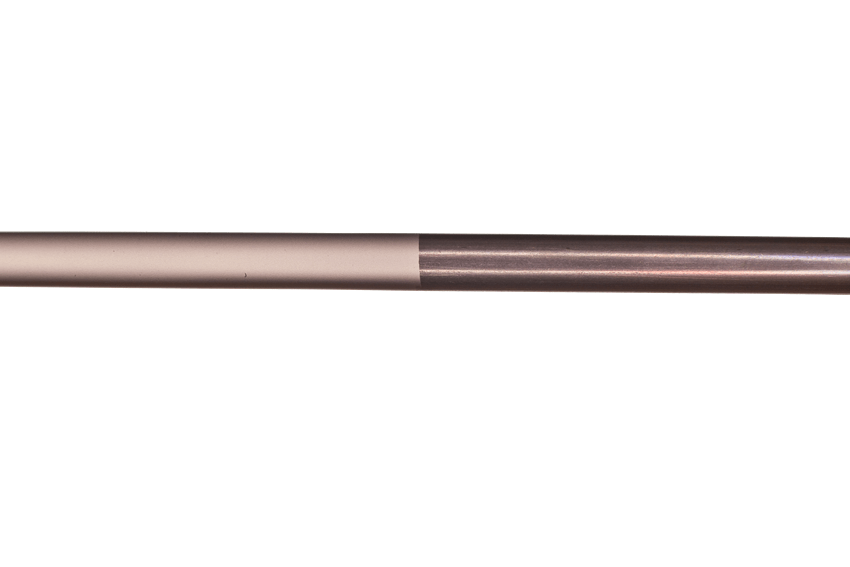

When developing the process through consultation with Vapormatt’s wire specialist, David Clements, it was found that wet blasting also offered a very effective solution for removing graphite lubricants from the steel wire. The consistent and uniform finishes achieved offer great cosmetic benefits whilst the gentle abrasion, typically with aluminium oxide, was able to quickly and effortlessly remove all graphite and preserve the substrate. Having also tested chemical pickling and electro-polishing it was found that the samples produced by Vapormatt gave the best results. The lack of substrate damage and cost effective solutions offered by Vapormatt made wet blasting a clear decision for all producers involved.

Vapormatt designed a unique manifold arrangement incorporating an array of blast guns suitably positioned to enable the wire to pass through a complete 360 degree controlled wall of wet blast. As well as increasing blast capacity by 33% Vapormatt looked closely at the barrelling effect of the nozzles. By altering the acceleration rate and focal points of each individual blast stream Vapormatt are now able to provide an extremely controlled and concentrated processing environment, allowing manufacturers to achieve a consistent and uniform surface finish. The controllability of the process has consequently allowed wires as small as 2mm in diameter to be processed.

The improved system, with its innovative manifold, has been a great success. Through effective design and extensive R&D users of Vapormatt systems are now able to achieve a very clean, bright finish at a processing speed of 75m/min.