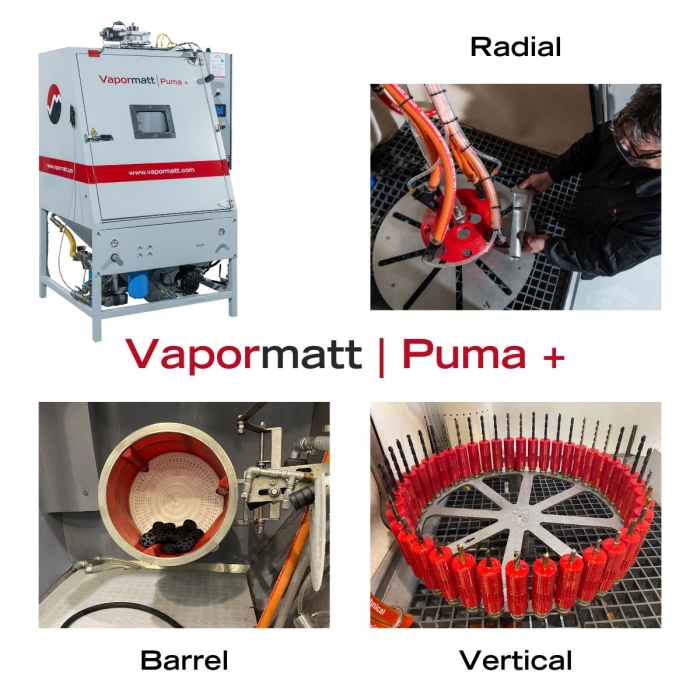

Our Puma + machine is ideal for those wanting to make the move from manual to automated wet blasting. Automation offers significant improvements in productivity and finishing consistency vs. manual finishing.

To make the Puma + as versatile and relevant to as many users as possible, we’ve developed 3 distinct variants...

Puma + Radial

The Puma + Radial is designed to allow the component’s surface to have full blast coverage in a medium size footprint whilst achieving the best results using our wet blast technology, ideal for the surface preparation of a vast range of different components. The machine has a driven turntable with 4 blast nozzles located on a head that traverses across the turntable in a sweeping motion.

Puma + Vertical

The Puma + Vertical is designed to automatically process taller component’s surfaces. The machine has a driven turntable with 2 blast nozzles mounted on a vertical oscillation arm located on the side of the turntable.

The machine can also be specified with up to 42 satellites, designed to automatically process round shank tools such as solid carbide end mills, drill bits and taps. Round shank tools from 3mm (0.12”) to 25.4mm (1”) in diameter and up to 300mm (12”) in length can be processed.

Puma + Barrel

The Puma + Barrel is designed to automatically process various small components such as additive manufactured parts. Two capacity barrels are available 350 (14”) and 500mm (20”) OD, with a loading capacity of up to 50kg (110lb) dependent on the option selected. The barrel is bi-directional making it ideal for surface cleaning and polishing.