A measure of tool quality is the durability of its cutting edge. In the same way a highly sharpened pencil is prone to snapping, a tool’s cutting edge when highly sharpened can be easily chipped and damaged.

The solution is to apply a specific edge hone (or rounded edge) that helps prevent the cutting edge from being damaged by chipping or curling and that also allows the tool to run at full production speed from new.

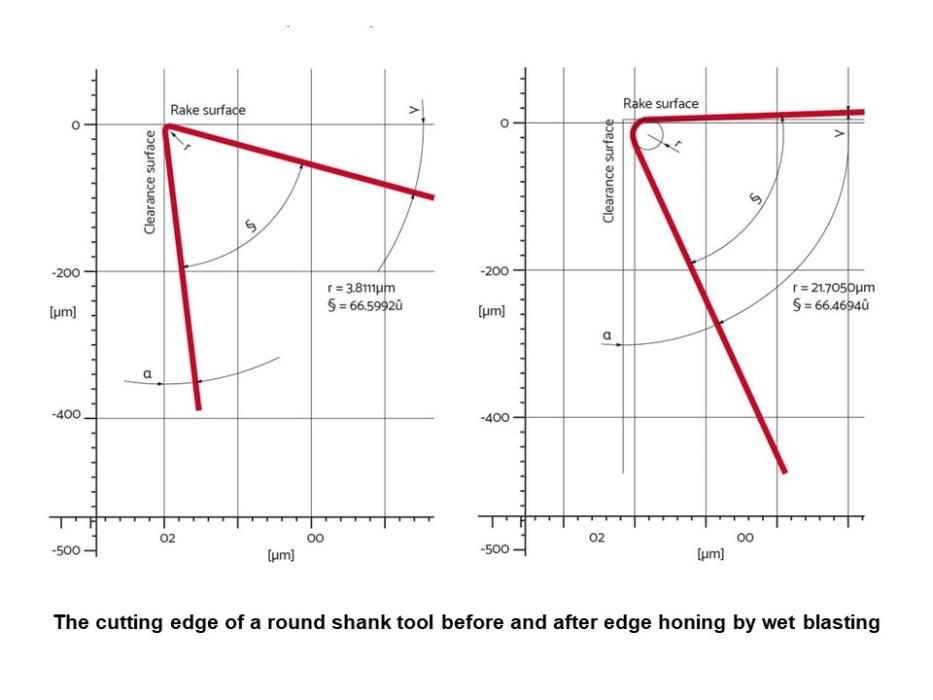

Our world leading wet blasting technology can apply this edge hone to a specific micrometre tolerance and profile, otherwise known as a K-factor, to suit the application the tool is designed for. Profiles can range from a waterfall hone with a K-factor greater than one to a reverse waterfall or trumpet hone with a K-factor of less than one.

And our wet blasting technology can apply an edge hone more accurately and consistently than other honing technologies like drag finishing.

'One of our customers was re-sharpening high-performance drills but was not edge-honing them. Using our automated Oncilla wet blasting machine, they applied a specific edge hone which increased tool life by five to seven times.'

So, as well as being highly relevant to tool manufacturers, our edge honing technology allows re-grinders to make old tools perform like new tools - or even better!

And a tool that stays sharp for longer means fewer tool changes and less downtime.