Our robust automatic Cougar + wet blasting machine (or vapor blasting machine) has been designed with tough extrusion die cleaning operations in mind.

And because the requirements for extrusion die cleaning vary from one manufacturer to the next, we’ve designed the Cougar + to be highly configurable so it’s an excellent fit for all sorts of operations.

Some of the configurable options include…

- Single load end with automatic door for improved productivity and ease of loading and unloading dies. A Cougar + configured with a single load end can easily process up to 80 dies a day.

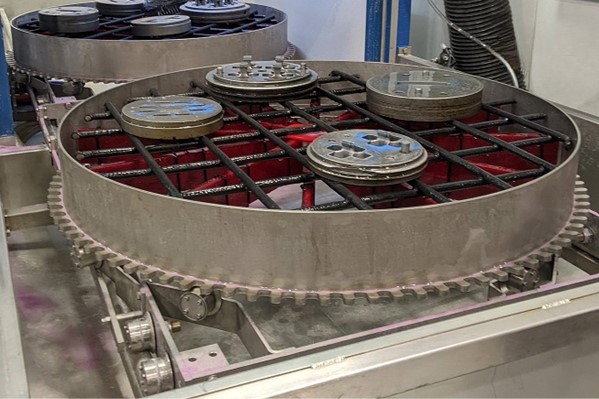

- Double load end with twin automatic doors so one turntable of extrusion dies can be unloaded and loaded whilst the other turntable of dies is being wet blasted. A Cougar + configured with a double load end can process up to 200 dies a day, or more if the dies are smaller.

- Top and bottom wet blasting crowns to speed up the cleaning time of the dies.

- Heavy duty turntables that can handle loads up to 1,000Kg.