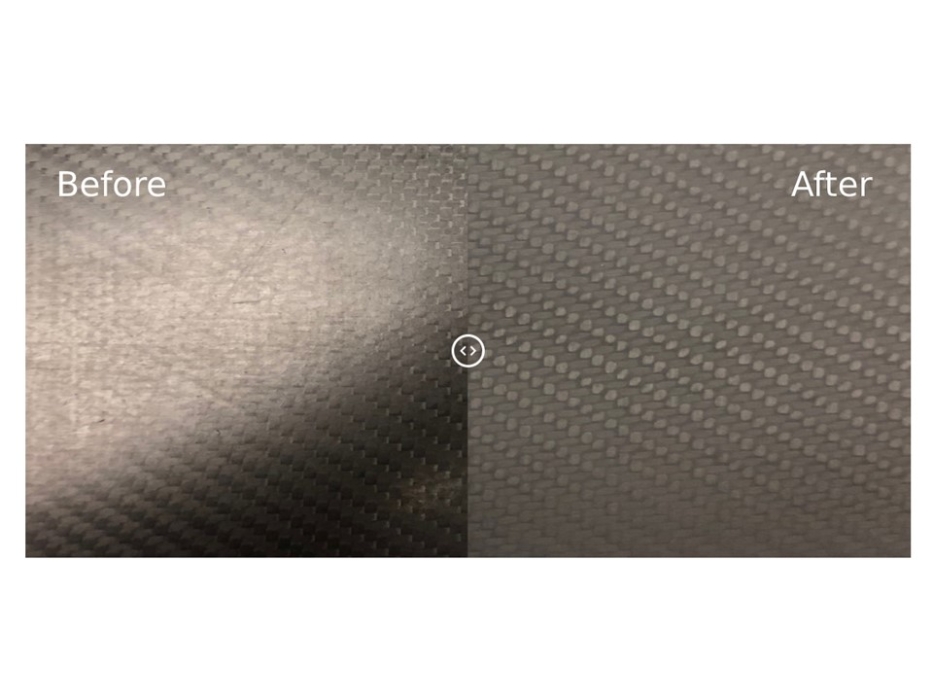

Wet blasting produces a highly clean ‘wet-out’ surface on carbon fibre that ensures excellent coverage of adhesives and coatings like lacquer and paint.

Unlike dry blasting, brush finishing, peel ply or sandpaper, there’s no risk of damaging fibres thanks to the cushioning effect of water in the wet blast process.

Undamaged fibres ensure the integrity / strength of the component is maintained.

In addition, and unlike dry blasting, carbon fibre components don’t need to be cleaned and dried before wet blasting - helping to save valuable time and cost.