Enter wet blasting – a gentle yet powerful surface treatment that transforms AM parts. Here’s why leading industries (Aerospace, Medical, Automotive) are using it:

✅ Smoother Surfaces – Eliminates roughness and layer lines for superior aesthetics

✅ Enhanced Mechanical Performance – Reduces stress concentrators, boosting fatigue life

✅ Superior Coating Adhesion – Ideal for anodizing, PVD, and bonding applications

✅ No Heat Build-Up – Unlike dry blasting, it avoids overheating and material distortion

✅ Eco-Friendly and Dust-Free – Less waste, recyclable media, and safer handling

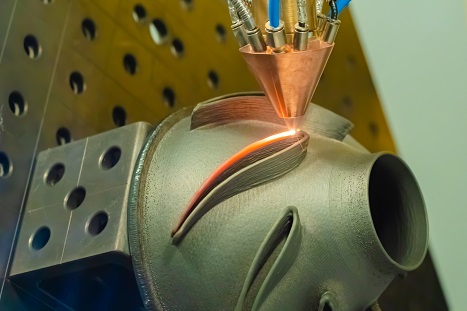

Whether it’s metal AM parts (DMD, SLM, DMLS, EBM) or polymer-based (SLS, SLA, MJF, FDM), wet blasting delivers precision, consistency, and quality.