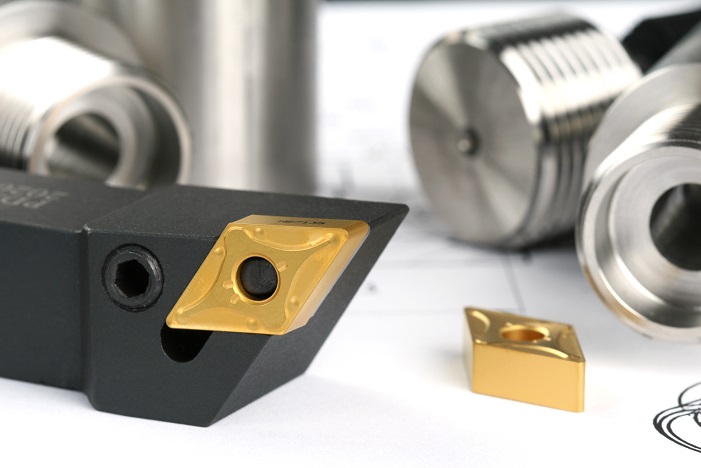

When it comes to precision machining, the smallest details can make the biggest difference. One such detail - the edge preparation of cutting tool inserts. Edge honing, particularly through wet blasting, is a game changer for improving tool life, performance, and consistency.

Why wet blasting for edge honing?

✅Enhanced tool life – By creating a uniform, controlled edge radius, wet blasting reduces chipping and wear, extending tool longevity

✅ Superior surface finish – The process smooths microfractures, leading to more stable cutting and improved surface quality on machined parts

✅ Consistent performance – Automated wet blasting ensures repeatability, reducing variability between inserts and optimising process reliability

✅ Improved coating adhesion – A properly honed edge allows for better coating adhesion, enhancing wear resistance and reducing friction

✅ Better cutting efficiency – The right edge preparation minimises cutting forces, reducing tool stress and improving material removal rates

For manufacturers looking to maximise productivity and reduce costs, wet blasting for edge honing is an investment that delivers measurable returns. Precision in edge preparation translates directly to precision in machining.