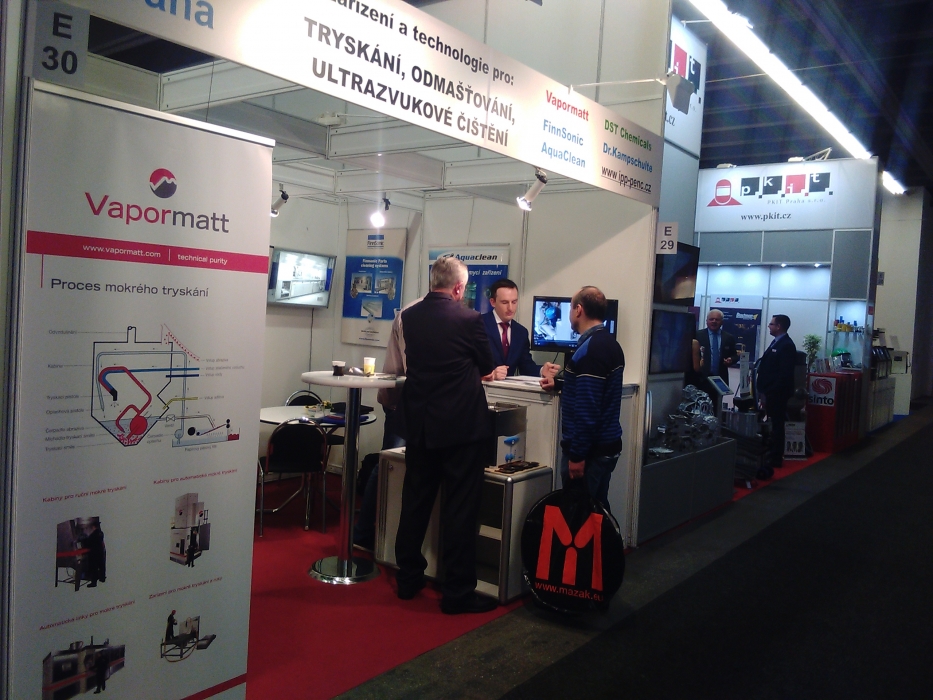

Visitors to the MSV show were able to see, for the first time, wet blast technology in the Czech market. Wet blasting is a strong alternative to dry sand blasting with clear benefits such as improved surface finishes. The machines are made by Vapormatt in the UK and have been sold all over the world. Vapormatt’s Agent, IPP Praha, had a Panther wet blasting machine on display at the Brno fair this year.

Unlike dry sand blasting the wet process uses water to add versatility and a lubricating effect to make wet blasting a good process for degreasing or improving the surface finish of components. The lubricating effect of wet blasting creates a flow of abrasive over the material, allowing more complex shapes to be processed – giving a surface that is more uniform and better prepared for coating, painting or bonding. Additionally wet blasting uses less abrasive media because the water protects the particles so that they do not break as quickly and there is also no dust because the water stops abrasive particles from going into the air and workshop.

Vapormatt are specialists in the design and development of high end wet blasting machines that are needed in advanced manufacturing where the control and repeatability are highly valued for creating difficult to achieve but consistent and surface finishes

The company also offers simpler machines and the “Panther” was in the spotlight at the Brno fair. The Panther is an entry level machine that is great for the cleaning of oily parts, the removing of welds from stainless steel pieces or any application where dry sand blasting is currently used. During the week many people visited and tested the wet blast process on their components. The wet blasting process was very popular and continued interest in the Czech Republic is expected.

For more information or to discuss and application please contact IPP Praha.