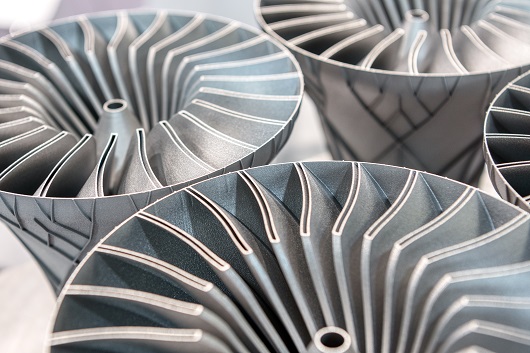

The liquid nature of wet blasting makes it ideal for penetrating the complex internal channels that are so typical of additive manufactured components.

Wet blasting rapidly removes un-sintered or partially sintered powder and even gives a visible indication the channel is clear when the blast slurry exits the channel.

This is in stark contrast to dry blasting where it is difficult to tell if the channel is clear and can even exasperate the problem by adding additional material to blocked channels.