Vapormatt has released a new white paper that examines the future of edge preparation and the benefits of wet blasting to the metalwork industry. The paper also outlines the latest wet blasting innovations that can meet customer demands for exceptional surface finish and the removal of chemicals from the edge honing process.

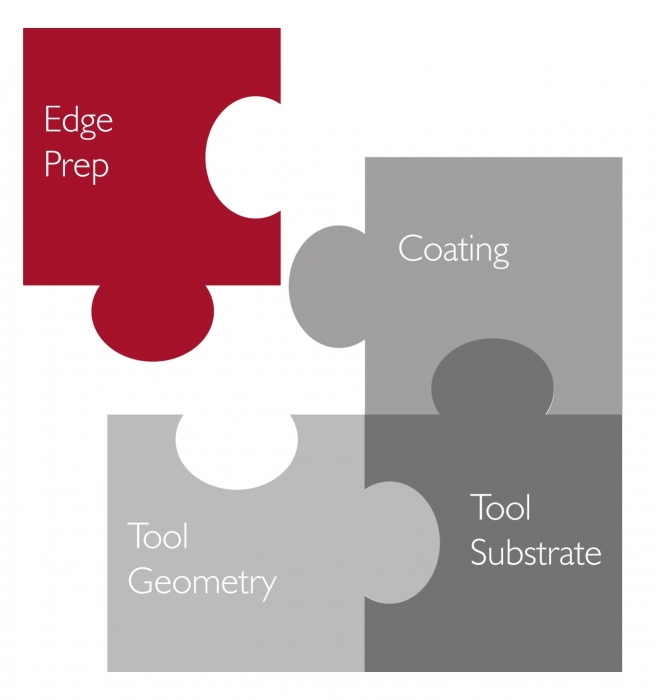

Increasing product efficiency and reducing waste has become more and more important to a wide range of industries that rely on the performance of cutting tools. Innovations in edge honing have made the preparation process more precise but also more customisable due to unique nozzle arrangements that significantly enhance output quality on a range of cutting tools.

Vapormatt’s white paper explores how wet blasting is the leading controlled edge honing, polish and cleaning process for customers to use to ensure the best possible surface finish. Wet blasting cleans and prepares surfaces by combining compressed air, abrasive media and water in a slurry form that is highly controllable allowing for more consistent results and reduced chipping/ surface degradation.

Vapormatt’s latest wet blasting innovation, the Vapormatt Sabre, was recently launched in March at GrindTec 2014, which saw a new record of over 15,300 visitors attend. The Vapormatt Sabre is a cost-effective, high performance wet blasting tool designed to significantly enhance output quality on a range of cutting tools.

Vapormatt will be exhibiting at IMTS 2014 between 8-13 September in Chicago, Illinois. Visitors to the event will find Vapormatt in the Tooling and Workholding Systems Pavilion at Booth W-2496.

The white paper can be downloaded for free from our website.